Indheater Pad

Powerful railway switch heating.

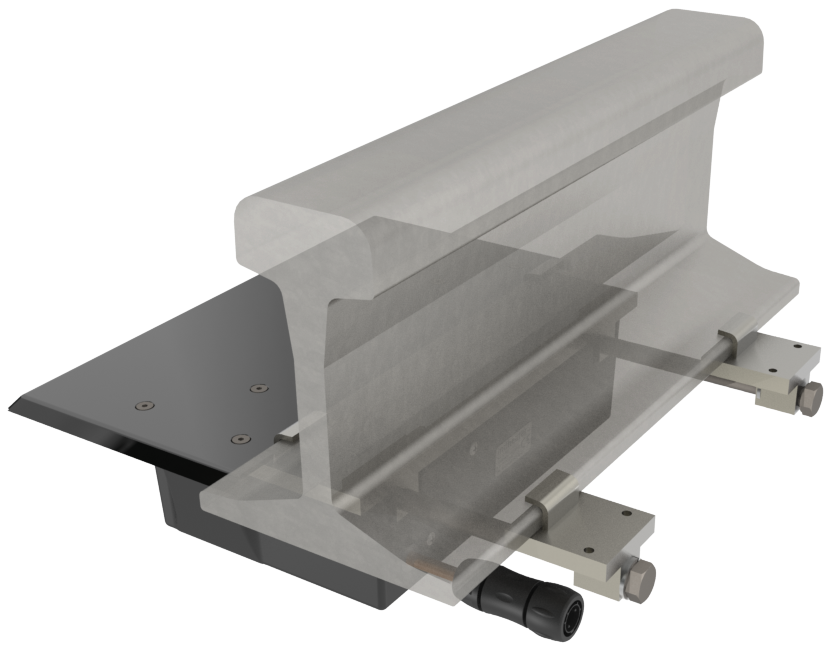

Based on structural design we have developed a variety of different units to ensure we can fit our units in all kind of rail way tracks. With our system we offer a complete package which guarantees the complete switch is maintenance free from manual sweeping and ice scraping.

Indheater offers 5 standard versions of pads, made for maximum performance and easy installation.

Designed to be installed on all standard rail tracks.

Rapid heating. Heat is immediately generated to the designated surface with minimum delay.

Individually controlled heat elements secure that the energy is used at the right spot of the switch.

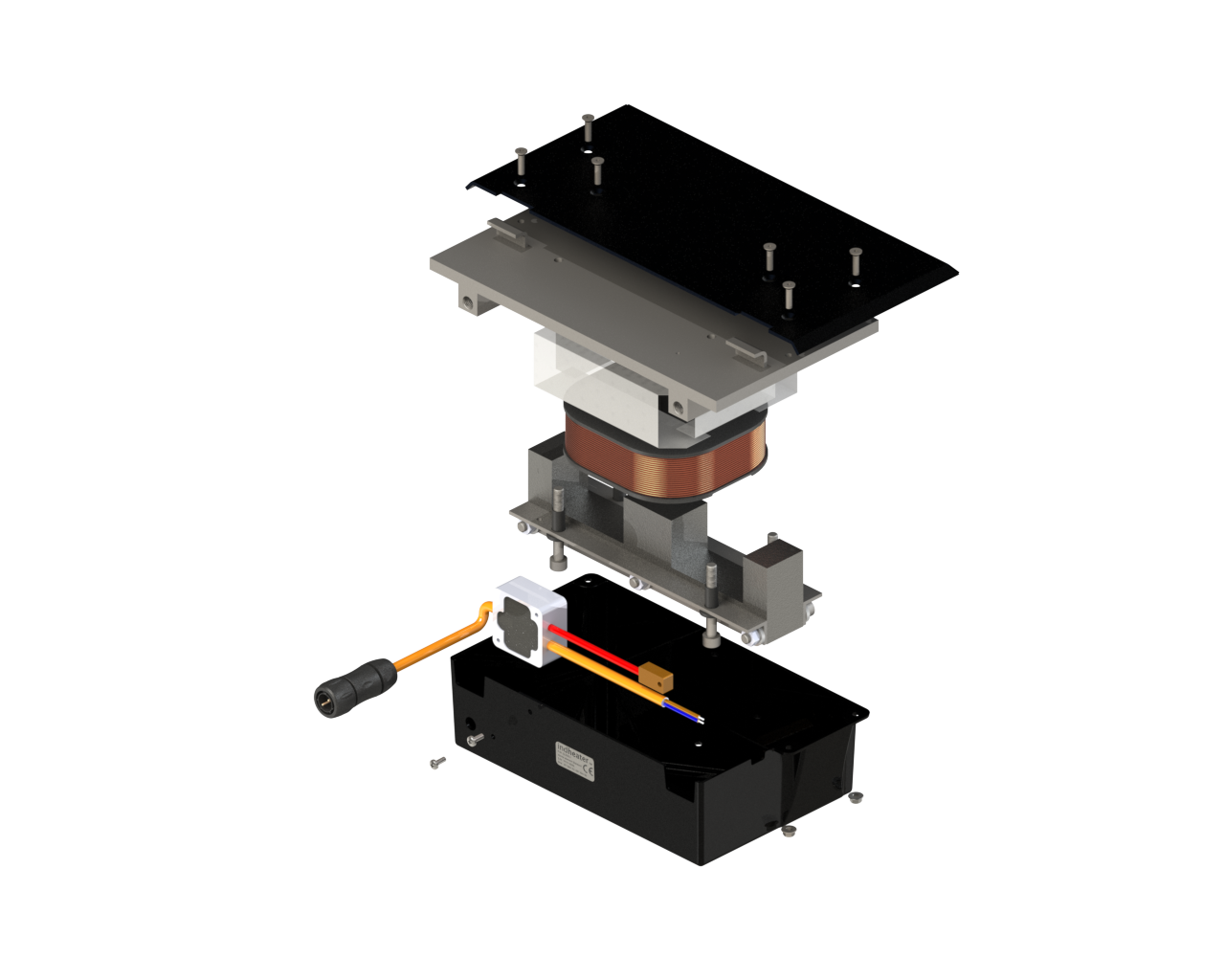

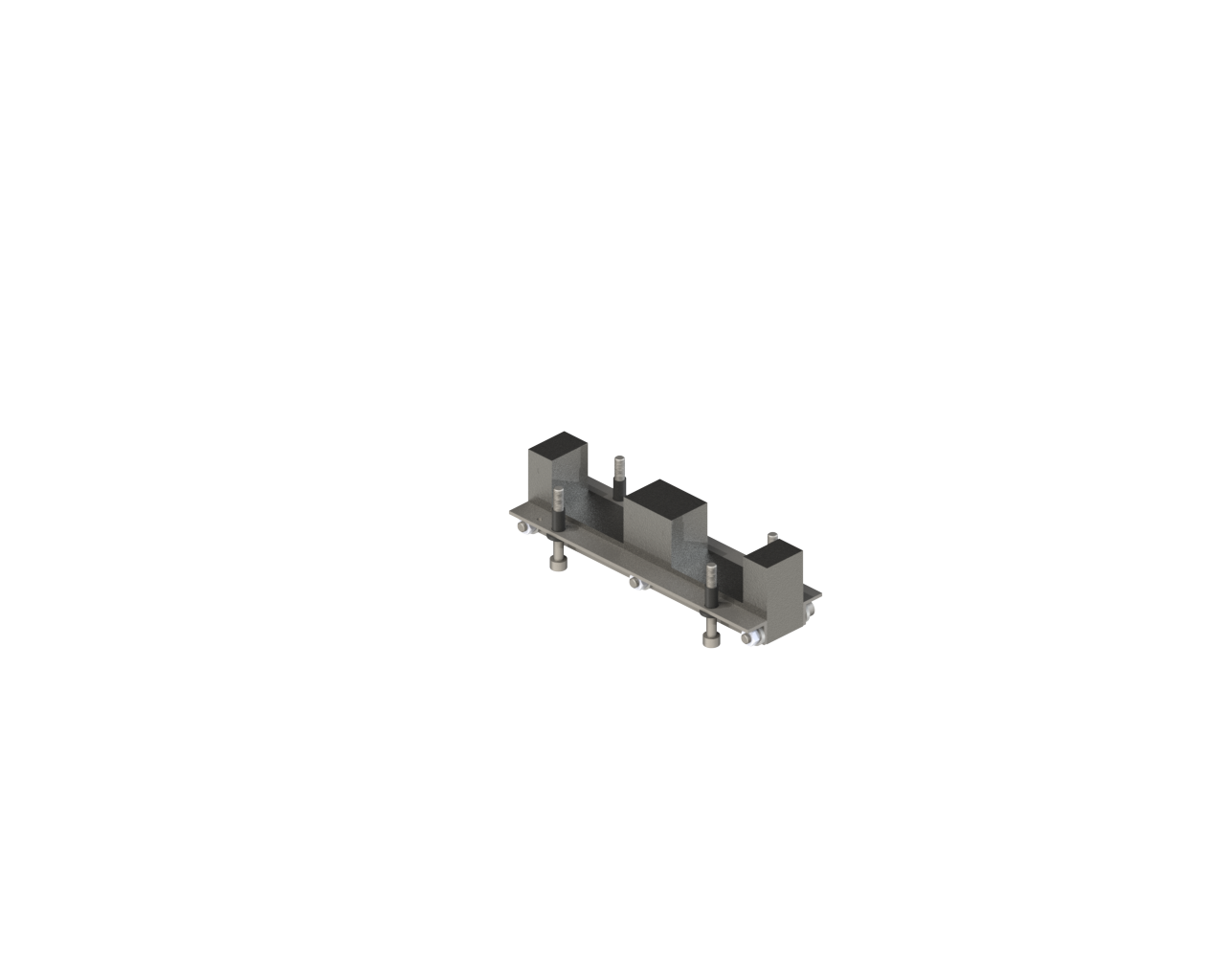

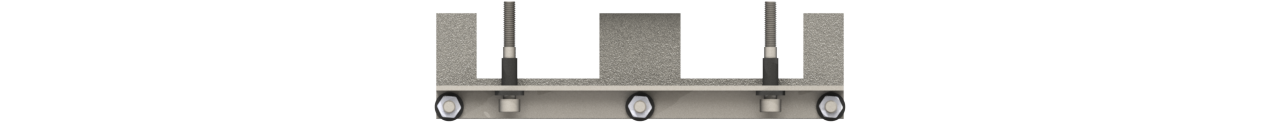

Explore the indheater pad robust design

Every part is carefully engineered and tested for rough winter conditions.

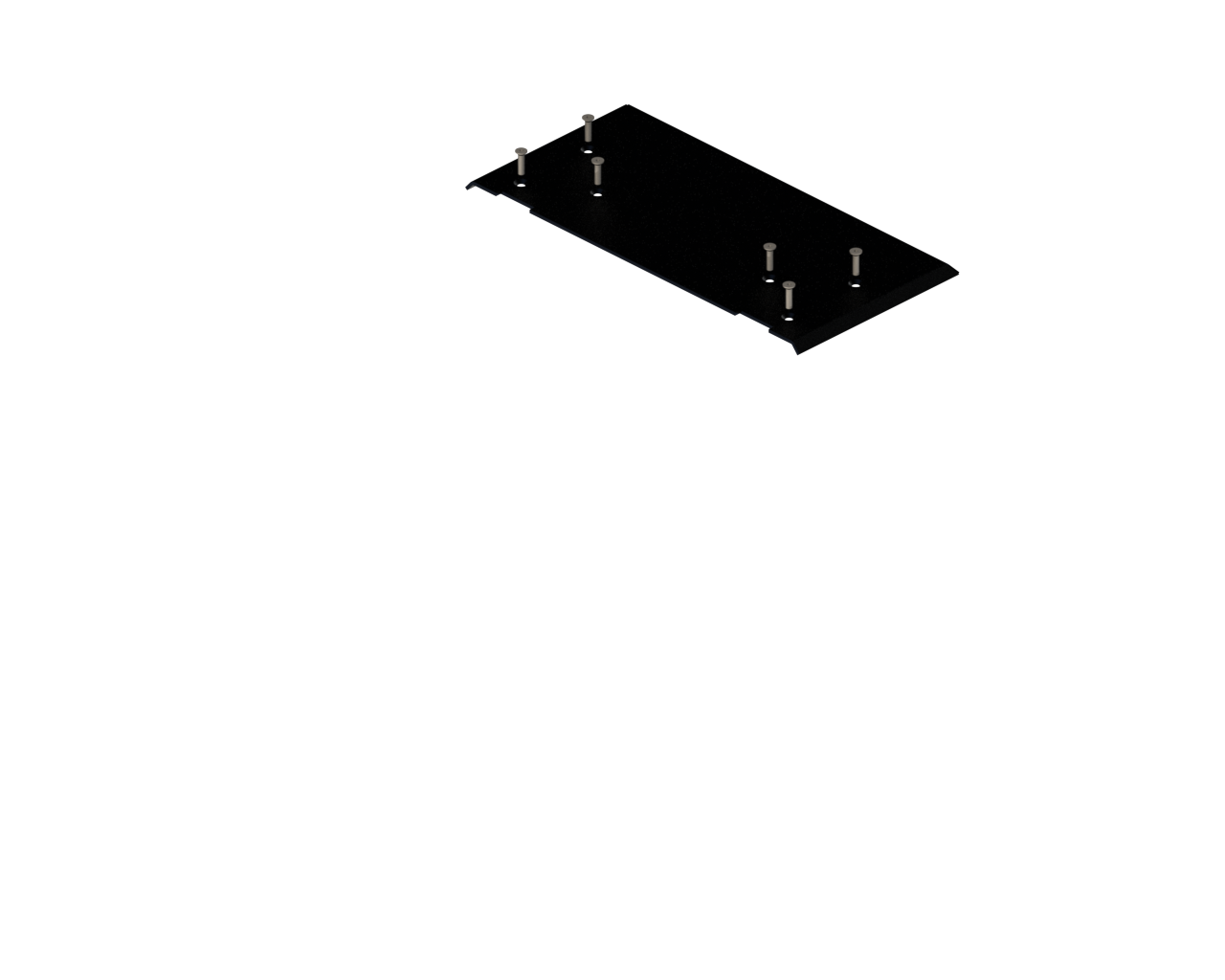

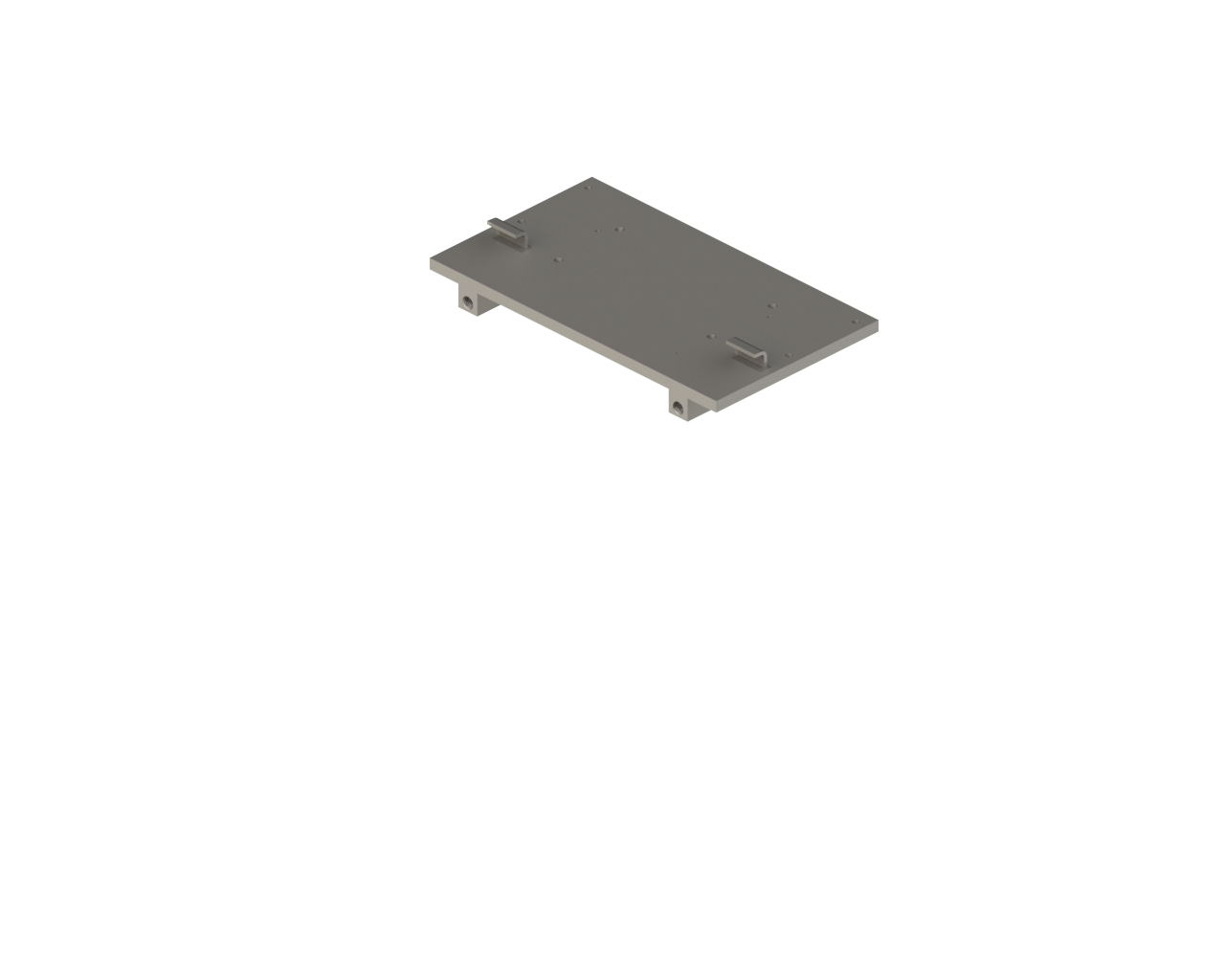

Heat distribution plate

Transferring and distributing the heat from the core plate to the critical areas between sleepers provides enhanced heat transfer. Made from coated aviation grade aluminum.

Core plate

Engineered to have to generate maximum heat absorption. Unique claw shape design optimize installation process.

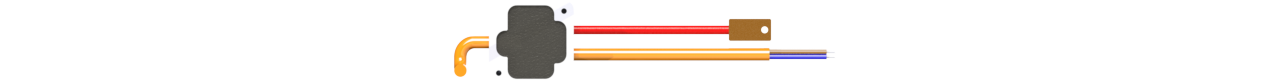

Insulation protection

Additional protection around coil to guarantee double isolation layers. Complies with electrical safety requirements for railway application.

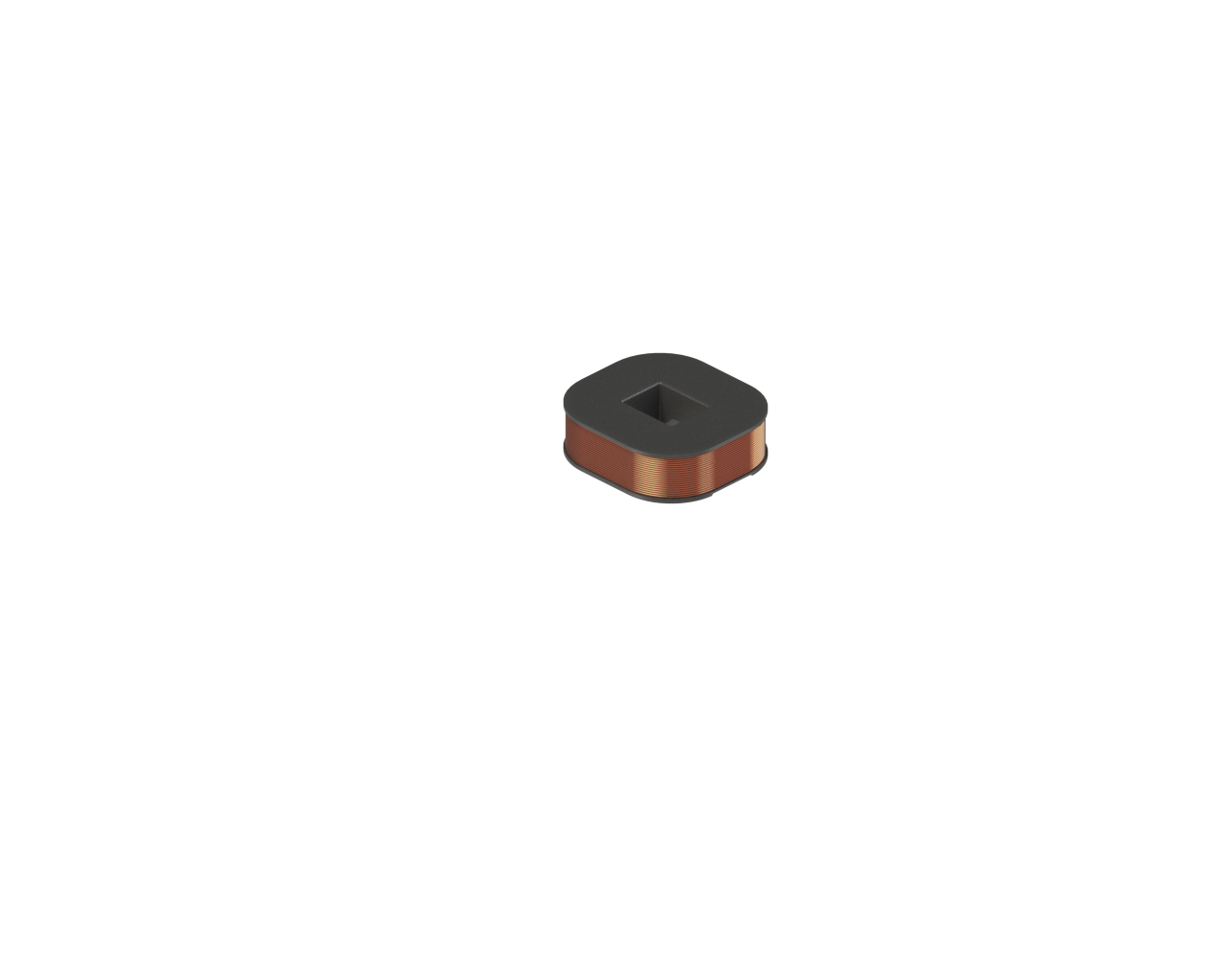

Induction coil

The induction coil class C-180 generates a magnetic flux to the core plate. Pre-heated vacuum coated process.

Induction E-Core

Manufactured with auto-punching to optimize efficiency and reduce noise.

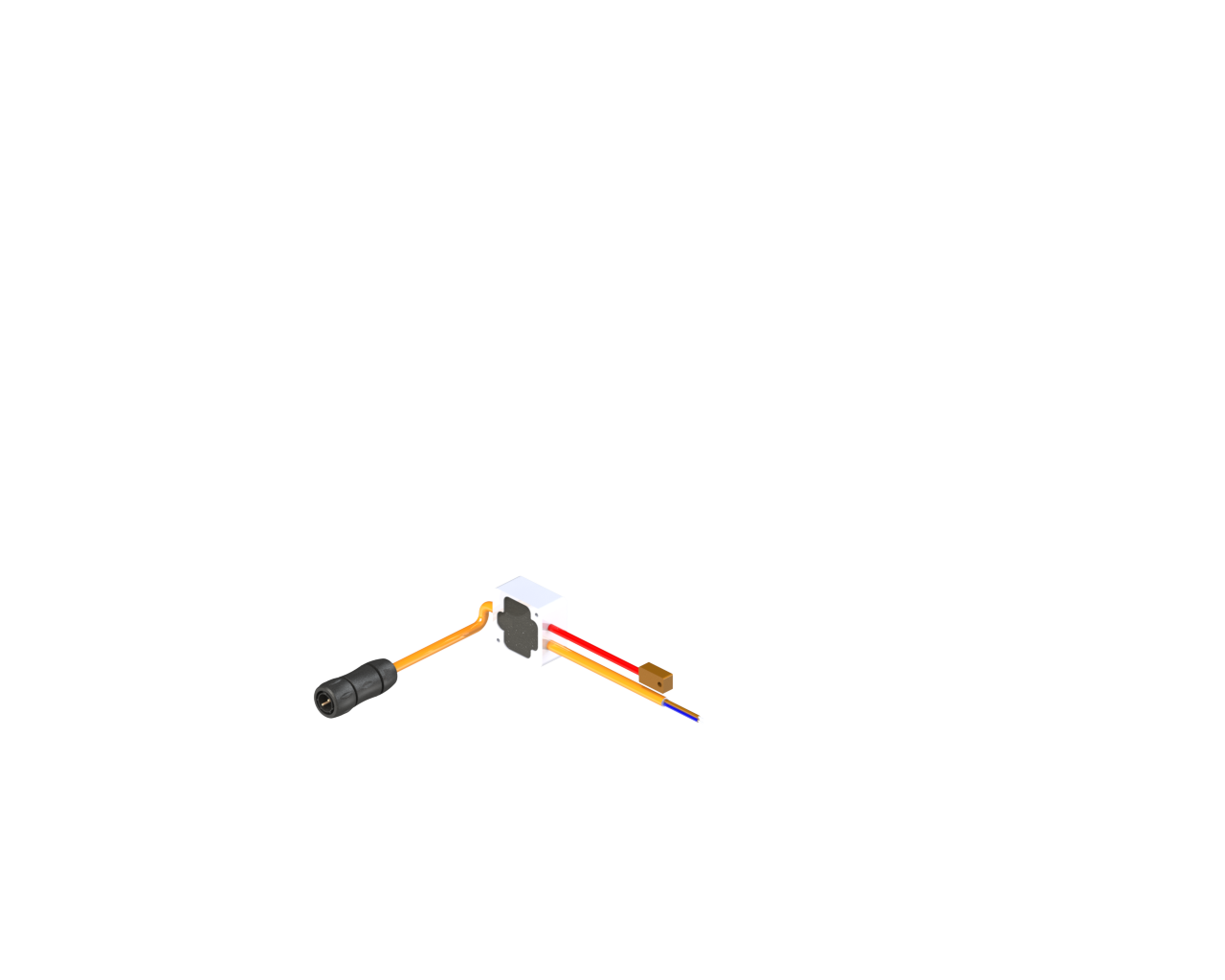

Control circuit

Carefully selected components molded in aviation graded heatsink to withstand high vibration and IP67 rating.

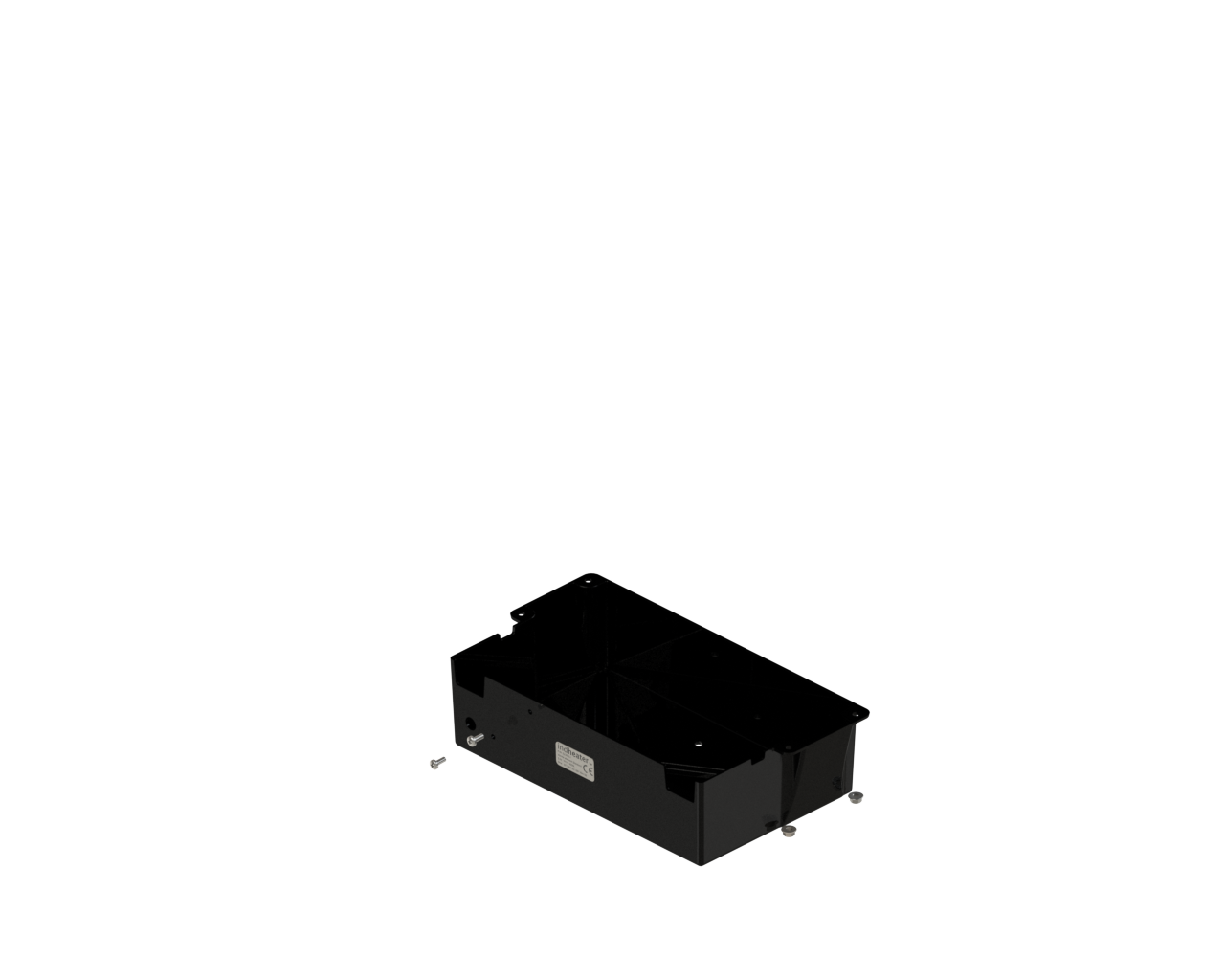

Protection enclosure

Designed to withstand shock, vibration, UV and chemical resistance.

Solidly engineered. Environmentally friendly.

Using aviation-grade quality materials with no moving parts, the Indheater Pad is built to withstand the toughest conditions imaginable while using no environmentally harmful chemical compounds or substances.

Indheater standard unit – E230351

Indheater staggrop right unit – E230352

Indheater staggrop left unit – E230353

Indheater 200mm unit – E230354

Indheater staggrop 70mm unit – E230355

The Indheater Systems in your railway infrastructure.

Contact us for an individual energy savings calculation and quote.

Become an Indheater Systems certified reseller.

Are you interested in working with us? Contact us for more information.

Need help with installation, service or maintenance?

Our expert technicians are available to assist in the event of problems.